|

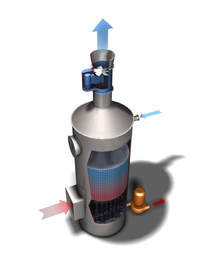

Thermal Energy International implemented a FLU-ACE® Condensing Heat Recovery System on the pulp machine exhaust at a pulp mill in Canada. Heat sources considered for the application included boiler plant flue gas, lime kiln scrubber exhaust, smelt dissolving tank scrubber exhaust, pulp dryer exhaust, and recovery boiler exhaust. Ultimately the pulp dryer exhaust was selected due to its proximity to users, high temperature and humidity, steady flow, and low fouling potential. The FLU-ACE system was designed to deliver some 50 MMBtu/hr of energy to plant systems (peak winter performance), saving 50,000 pounds and hour of steam to be fed back into existing steam turbines to generate more electricity. This energy was previously discharged and lost to the atmosphere in the form of hot air and water vapor in the pulp dryer exhausts. The “free energy” from the exhaust was used to heat and preheat:

The system was implemented on a turn-key basis and was completed on budget and schedule.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed