FLU-ACE® Heat Recovery

|

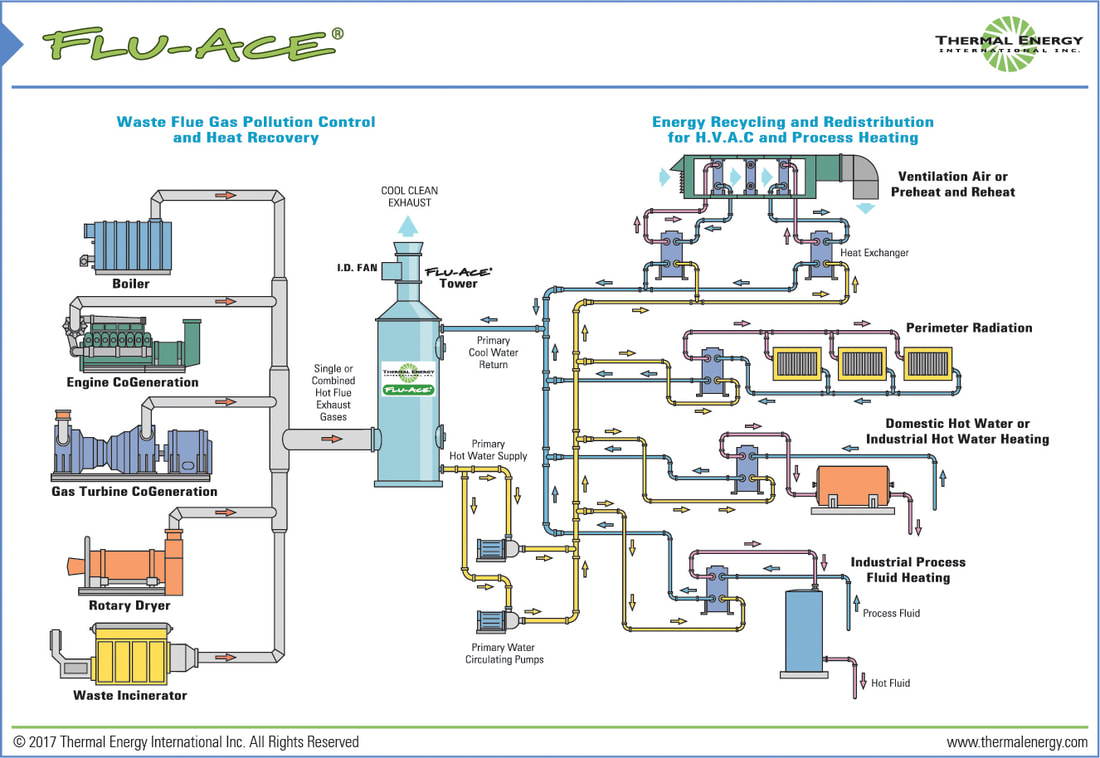

Reduce your fuel bills by 10% to 20% with Thermal Energy International’s FLU-ACE® heat recovery technology. For every $1,000 in fuel purchases for your boilers, $200 or more is wasted up your exhaust stacks. FLU-ACE® can typically recover up to $180 (or 90%) of that wasted energy and recycle it back into your processes and / or heating systems. The FLU-ACE® can also be used to save even more money recovering heat from power generation systems, evaporator exhausts, dryer exhausts, and other industrial heat sources. FLU-ACE® is a direct contact condensing heat recovery system that recycles the heat normally lost through the boiler flue gas exhaust. The key benefits are:

|

Click image to enlarge

|

- Reduce greenhouse gases and other emissions commensurate to fossil fuel reductions;

- Achieve typical water temperatures of up to 63°C/145°F (up to 82°C/ 180°F with alternate design);

- Recover 200% to 300% more heat than conventional recuperator and economizer systems … heat readily usable for process water and air heating; and

- Recover and condense between 70% and 90% of the water vapor normally vented in the exhaust gas… providing water for recycling to process.

FLU-ACE® is a well-documented and proven technology that has been helping our customers save energy and reduce carbon dioxide emissions for over 20 years.

|

Check out some success stories

|

See sector-specific applications

Visit our sectors section to see how FLU-ACE® technology has been applied in your sector. |

Learn more about FLU-ACE

|