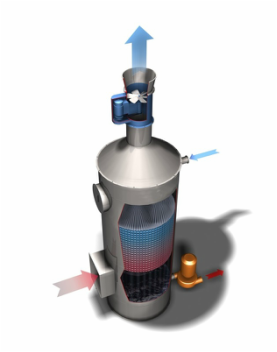

Condensing heat recovery can be applied in two ways: direct-contact and indirect-contact systems. An indirect-contact system is simply a standard heat exchanger: water passes through tubes and the hot exhaust passes outside the tubes. Sensible heat and latent heat are transferred through the tube walls from the hot side to the cold side. By contrast, direct contact systems bring the cold water medium in direct contact with the hot gas in an open spray tower or packed spray tower to recover the heat directly by heating the water. Neither of these technologies is a "one size fits all" solution," so it’s best to take a look at the pros and cons of each type before making the right choice for your facility. Some advantages and disadvantages of the two types of systems include: Direct Contact Economizer

Indirect Contact Economizer

Clearly the selection of either direct contact or indirect contact is dependent upon the specific process heating application, both on the characteristics of the heat source and the heat sink. For more on this topic see our white paper entitled Condensing Heat Recovery – The Final Step towards the 95% Efficient Boiler Plant, as published in Process Heating, Volume 22, Number 2.

0 Comments

|

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed