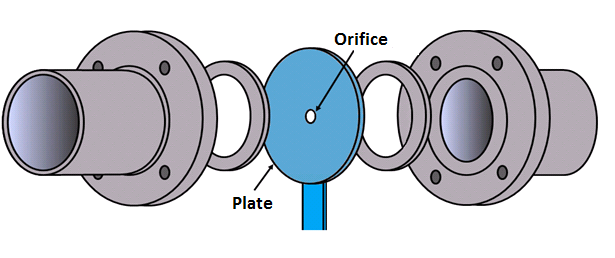

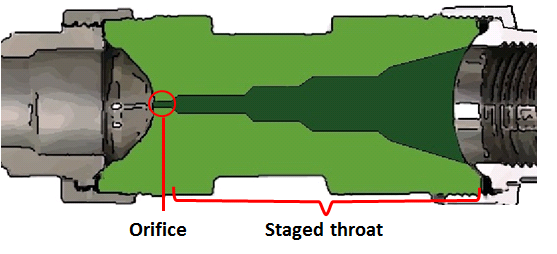

"A steam trap is a device used to discharge condensate and non-condensable gases with a negligible consumption or loss of live steam. Most steam traps are nothing more than automatic valves. They open, close or modulate automatically." The first sentence defines the function of a steam trap. All steam traps must remove condensate and non-condensable gases without losing any live steam. The second sentence explains the function of a steam trap in the simplest way. The keyword to note from this sentence is - most. This is where orifice type steam traps differ. Only mechanical type traps contain a valve. Orifice type traps do not contain any moving parts. So how do they function? There are two main types of orifice traps, (1) fixed or plate orifice trap, and (2) venturi orifice traps. Unlike a conventional mechanical steam trap, an orifice steam trap continuously removes condensate from a system. They allow any condensate present in the steam line to pass into the condensate return system as it is formed. The operation of the trap is based on the difference in density between water and steam. At low pressures, the density of condensate is about 1,000 times greater than that of steam. In the case of a small orifice, the condensate flows with much lower velocity through the opening, than steam. If both media are present, the much denser condensate will stop the steam from passing through. This means that no live steam will leak through the trap. Although fixed and venturi traps work on the same principle, there is one key difference between them. A fixed or plate orifice trap consists of a small orifice machined into a plate. The size of the orifice used is determined by the pressure and condensate flow through the trap. As condensate is forced through the orifice it passes from an area of high pressure into a lower pressure region. Water’s capacity to contain energy reduces as pressure reduces and so any excess energy which cannot be contained due to the pressure drop serves to instantly evaporate a proportion of the liquid water. This evaporation is known as flashing, and the instantaneous expansion of the flash steam creates a back pressure which prevents live steam from passing, and protects the orifice from erosion. However, this means that fixed orifice traps can only effectively drain condensate for a specific condensate flow condition, meaning that this type of trap cannot handle loads that are varying. If the amount of condensate which needs to be discharged reduces, the condensate plug at the orifice, created by localized back pressure from the flash expansion, will not be present. This will lead to live steam being lost. Conversely, if the condensate load exceeds the design flow for the orifice plate, then condensate will back up which may affect process temperatures or lead to waterhammer. If you search for the definition of a steam trap Google will give you the following result: A venturi orifice trap works on the same principle, but with is one vital difference - It is designed to handle varying loads. Following the orifice there is a cleverly configured staged throat that is individually sized for its application and varying condensate loads. The staged throat is designed to create a variable back pressure at the orifice as the load changes. At lower flow rates the condensate flashes close to the orifice whereas at higher load conditions it flashes further down the stage throat. This restricts the condensate flow through the orifice depending on the load. So venturi traps can self-regulate their capacity across a range suitable for the vast majority of industrial applications. The GEM steam trap is a venturi orifice type trap. The engineers at Thermal Energy International ensure that our GEM traps are sized correctly; maximizing the energy saved compared to conventional mechanical traps and fixed (or plate) orifice traps. Mechanical traps tend to have much larger orifice sizes, so when failing open, or even partially open, the steam losses can be substantial. Mechanical traps can often fail closed which can have catastrophic consequences on a site due to the resulting waterhammer.

Key advantages of a venturi orifice trap:

Thermal Energy's GEM steam traps are the most efficient and reliable steam traps on the market. Our high quality product and service enables us to supply GEM steam traps with a 10-year performance guarantee. See why our customers prefer our GEM steam traps over conventional steam traps.

3 Comments

|

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed