|

Thermal Energy International provides the optimal solution for pulp and paper companies looking to fight climate change and earn a high return on investment. In fact, our largest projects to date (including our $11 million project with Resolute FP) have been in the pulp and paper sector. So we sent Antoine Hofer, our Technical Sales Director for Quebec and Eastern Canada, to International Pulp Week in Vancouver to meet with the world’s leading producers of market pulp, and tell them about our amazing steam and heat recovery technologies that save mills millions in energy costs every year. International Pulp Week 2018 is a 3-day conference (May 6 - 8) organized by the Pulp and Products Council (PPPC). The event at the Hyatt Regency Hotel Vancouver brings together the global pulp and forestry sector community, providing a home-base for the industry’s senior executives. In addition to multiple half-days of conferences and group discussions, it also includes networking sessions, and the final day is reserved for private meetings and further networking. Want to learn more about how Thermal Energy International reduces pulp and paper companies' energy bills and cuts their carbon emissions? Check out the case studies on our Pulp and Paper page by clicking the button below.

0 Comments

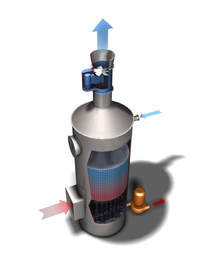

Back in December we announced an $11 million energy efficiency project with Resolute FP Canada Inc. The project, which included the installation of two FLU-ACE® Heat Recovery Systems and the conversion of the mill’s steam traps to Thermal Energy’s proprietary GEM Steam Trap system, represents the Company’s largest heat recovery and largest GEM orders to date. Recently, four of our engineers went to the Resolute pulp and paper mill in Thunder Bay, Ontario to conduct an onsite survey and specification process to properly size and replace the facility’s existing mechanical traps with high-efficiency GEM Steam Traps. For more details on this project, please read our article below courtesy of ACCESS Magazine. Thermal Energy International implemented a FLU-ACE® Condensing Heat Recovery System on the pulp machine exhaust at a pulp mill in Canada. Heat sources considered for the application included boiler plant flue gas, lime kiln scrubber exhaust, smelt dissolving tank scrubber exhaust, pulp dryer exhaust, and recovery boiler exhaust. Ultimately the pulp dryer exhaust was selected due to its proximity to users, high temperature and humidity, steady flow, and low fouling potential. The FLU-ACE system was designed to deliver some 50 MMBtu/hr of energy to plant systems (peak winter performance), saving 50,000 pounds and hour of steam to be fed back into existing steam turbines to generate more electricity. This energy was previously discharged and lost to the atmosphere in the form of hot air and water vapor in the pulp dryer exhausts. The “free energy” from the exhaust was used to heat and preheat:

The system was implemented on a turn-key basis and was completed on budget and schedule. Improving energy efficiency in the industrial sector is being prioritised in many countries because of its importance in the pursuit of energy supply security, increasing economic competitiveness and in reducing greenhouse gases emissions. One of the most energy-intensive industries in North America and Europe, is pulp and paper. According to Statistics Canada, in 2014, the pulp and paper industry accounted for 24% of the total energy consumed by all manufacturing operations in the country. This was down from 31% in 2005. This decline reflects changes in the demand for certain paper products such as newsprint (Canada’s primary newsprint market, the United States, witnessed a considerable fall-off in newspaper circulation as more readers migrated to digital media sources), as well as energy efficiency improvements at various mills. Typical paper mills use most of their energy in the pulping and drying processes, but the specific energy consumption in pulp and paper production is a result of several factors, including plant size, product mix, processes used, the technical age of the mill, feedstock quality, plant capacity utilization, and climate conditions. Investment to improve energy efficiency in the pulp and paper industry can deliver large energy savings, improved productivity, and reduced environmental pollution. Opportunities to improve energy efficiency include: heat recovery, cogeneration, increased use of (self-generated) biomass fuel, and increased recycling of recovered paper, efficient motors and improved efficiency of steam use. The pulp and paper industry requires a typically high amount of power and heat in forms of hot air and/or steam. And, with such a high, steady demand for heat as well as power, many pulp and paper plants are perfectly positioned to take advantage of the benefits offered by Thermal Energy’s best-in-class heat recovery, cogeneration, and steam trap solutions.  Our FLU-ACE® heat recovery technology can recover as much as 90% of the heat normally lost through dryer section / hood exhausts in the form of water at 50°C to 70°C. This is possible using the FLU-ACE’s unique direct contact (gas/liquid) packed-tower design, enabling optimal recovery of both sensible and latent heat, in widely varying operating conditions. The pulp and paper industry remains a prime candidate for cogeneration. Thermal Energy’s Super-Efficient Cogeneration™ solutions can provide up to 70% savings on electrical costs at a self-generated kWh cost of less than $0.04/kWh, and an additional 10% to 20% natural gas energy savings from up to 90% recovery of heat losses from existing exhaust streams.  Our GEM™ steam traps help pulp and paper manufacturers achieve a 10% to 20% permanent reduction in steam costs. GEM steam traps have no moving parts, require virtually no maintenance, and come with a ten-year “no fail” performance warranty, which means increased reliability and less maintenance costs. Venturi orifice designed GEM steam traps can help eliminate water hammering problems, eliminate the cost of replacing failed traps, and improve a plant’s production output. Our pulp and paper customers recognize their social obligations and their role in the communities and countries in which they operate. In fact, many proactive forest-industry companies have brought responsible business practices visibly into their corporate strategies and communication efforts. We look forward to continuing to work with pulp and paper companies in helping them achieve their corporate energy savings and greenhouse gas reduction goals. Resulting emissions reduction expected to be equivalent to preventing the burning of more than 21 million kilograms of coal per year OTTAWA, ONTARIO– December 5, 2017 – Thermal Energy International Inc. (“Thermal Energy” or the “Company”) (TSX-V: TMG), a global provider of industrial and institutional energy efficiency solutions, has been engaged by an existing pulp and paper customer to design, develop and implement a major energy efficiency improvement and greenhouse gas reduction project. The project includes the installation of two of Thermal Energy’s proprietary FLU-ACE® Heat Recovery Systems and the conversion of the mill’s steam traps to Thermal Energy’s proprietary GEM™ Steam Trap system. Once completed, the $11 million project is expected to provide the customer with annual natural gas savings of more than 35%, while reducing its annual greenhouse gas emissions by more than 20%, or approximately 43,000 metric tonnes. “Pulp and paper is one of the most energy intensive sectors and our energy efficiency solutions represent a win-win scenario," said William Crossland, CEO of Thermal Energy. "We have been working in partnership with this customer over the past year to develop a turn-key project that meets both their energy savings and greenhouse gas reduction goals. This resulted in our largest single order to date and a project that can serve as a blueprint for other large energy users around the world looking for an optimal solution for fighting climate change, by providing significant reductions in carbon emissions and energy use while, at the same time, delivering a high return on investment.” The estimated annual reduction in greenhouse gas emissions resulting from the project, once complete, is equivalent[1] to:

This project represents Thermal Energy’s largest heat recovery and largest GEM orders to date and is expected to be substantially completed and revenue earned over the next 18 months. [1] United States Environmental Protection Agency’s Greenhouse Gas Equivalencies Calculator: www.epa.gov/energy/greenhouse-gas-equivalencies-calculator [2] The Cost of Wind Energy in the US: www.awea.org/falling-wind-energy-costs About Thermal Energy International Inc.

Thermal Energy International Inc. is an established global supplier of proprietary, proven energy efficiency and emissions reduction solutions to the industrial and institutional sectors. We save our customers money and improve their bottom line by reducing their fuel use and cutting their carbon emissions. Our customers include a large number of Fortune 500 and other leading multinational companies across a wide range of industry sectors. Thermal Energy is also a fully accredited professional engineering firm and by providing a unique mix of proprietary products together with process, energy and, environmental engineering expertise, Thermal Energy is able to deliver unique turnkey projects with significant financial and environmental benefits for our customers. Thermal Energy's proprietary products include; GEMTM - Steam traps, FLU-ACE® - Direct contact condensing heat recovery, and Dry-Rex® - Low temperature biomass drying systems. Thermal Energy International Inc. has offices in Ottawa, Canada as well as Bristol, U.K., United States, Germany, Italy and China. The Company’s common shares are traded on the TSX Venture Exchange (TSX-V) under the symbol TMG. For more information, visit our website at www.thermalenergy.com and follow us on Twitter at http://twitter.com/GoThermalEnergy. William Crossland President and CEO Thermal Energy International Inc. 613-723-6776 [email protected] Trevor Heisler Investor Relations Heisler Communications 416-500-8061 [email protected] # # # This press release contains forward-looking statements relating to, and amongst other things, based on management’s expectations, estimates and projections, the anticipated effectiveness of the Company’s products and services and the timing of revenues to be received by the Company. Information as to the amount of heat recovered, energy savings and payback period associated with Thermal Energy International’s products are based on the Company’s own testing and average customer results to date. Statements relating to the expected installation and revenue recognition for projects, statements about the anticipated effectiveness and lifespan of the Company’s products, statements about the expected environmental effects and cost savings associated with the Company’s products and statements about the Company’s ability to cross-sell its products and sell to more sites are forward looking statements. These statements are not guarantees of future performance and involve a number of risks, uncertainties and assumptions. Many factors, some of which are outside of the Company’s control, could cause events and results to differ materially from those stated. Fulfilment of orders, installation of product and activation of product could all be delayed for a number of reasons, some of which are outside of the Company’s control, which would result in anticipated revenues from such projects being delayed or in the most serious cases eliminated. Actions taken by the Company’s customers and factors inherent in the customer’s facilities but not anticipated by the Company can have a negative impact on the expected effectiveness and lifespan of the Company’s products and on the expected environmental effects and cost savings expected from the Company’s products. Any customer’s willingness to purchase additional products from the Company is dependent on many factors, some of which are outside of the Company’s control, including but not limited to the customer’s perceived needs and the continuing financial viability of the customer. The Company disclaims any obligation to publicly update or revise any such statements except as required by law. Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release |

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed