|

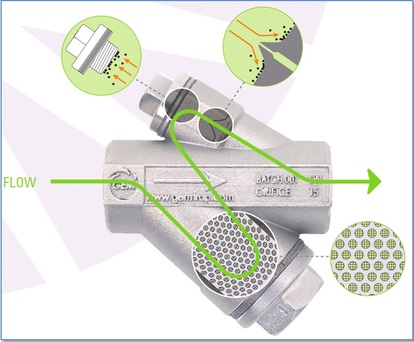

Steam traps are an essential part of a steam system. Unfortunately, conventional mechanical traps are often wasteful and laborious to maintain. As such, there has been much discussion on the energy that can be recovered by properly monitoring and maintaining steam traps. It is considered best practice for sites to have an annual steam trap survey to determine failures and replace any failed traps. More recently there has been the encouraged use of wireless monitoring to keep on top of maintenance and ensure that a failed trap is located quickly and then repaired. Wireless monitoring is a great step forward, and when paired with low maintenance steam traps, could be the optimum solution for steam users. On average, 10% of mechanical steam traps fail annually. These steam traps can either fail open or closed. When they fail open they leak live steam which is inefficient, wasteful and can pressurise condensate recovery lines. When they fail closed, the condensate can back up causing waterhammer and if not detected quickly, can be catastrophic as it causes pipework to erode, and at times, the implosion of pipework. What is the solution? It is the moving parts in mechanical traps that cause them to fail in either the open or closed position. Low maintenance steam traps like our venturi orifice GEM steam traps can provide the ultimate solution. GEM steam traps do not contain any moving parts and therefore removes the possibility of a trap failing. How does it work? Unlike most mechanical steam traps, a venturi orifice steam trap continuously removes condensate from a system. It allows any condensate present in the steam line to pass into the condensate return system the moment it is formed. The operation of the trap is based on the difference in density between water and steam. At low pressures, the density of condensate is about 1,000 times greater than that of steam. When both media are present, the much denser condensate will be preferentially discharged and stop the steam from passing through the orifice. The size of the orifice of each trap should be determined by the specific pressure and condensate flow through that trap. Each trap should be engineered to ensure a small plug of condensate is present at the orifice at all times. This means that no live steam can leak through the trap and it protects the orifice from any erosion by live steam. As condensate is forced through the orifice it passes from the area of high pressure into a lower pressure region in the throat of the trap. Water’s capacity to contain energy reduces as pressure reduces and so any excess energy in the condensate, which can no longer be contained due to the pressure drop, instantly evaporates once in the throat of the trap. This evaporation is known as flashing, and the instantaneous expansion of the flash steam creates a localised back pressure on the orifice. It is not just the orifice that should be sized specifically for the application the steam trap serves; the throat is also specifically configured. The throat contains a number of different stages of varying diameters. At lower flow rates the condensate flashes close to the orifice in a smaller diameter stage whereas at higher load conditions it flashes further down the throat in a larger stage. The flash point moves up and down the throat under variable loads. The pressure on the orifice applied by the flashing therefore depends on the flowrate, meaning venturi orifice traps can self-regulate their capacity and work effectively across a range suitable for industrial applications. The GEM steam trap is a venturi orifice type trap. The engineers at Thermal Energy International take full responsibility for accurately sizing the internal configuration of each and every trap, using their extensive experience to ensure GEM traps work effectively across variable loads, and do not pass live steam, maximizing potential energy savings. Low maintenance solutions As venturi orifice traps contain no moving parts that can wear, seize and fail, they require less maintenance than mechanical steam traps. They eliminate the need for the traditional cycle of ‘trap failure - identification of failed trap -replacement of failed trap’. With any steam trap, it is best practice to clean the strainer baskets once a year, and rather than identifying and replacing a failed mechanical trap, a smaller orifice on a venturi orifice trap may simply require a poke to remove any small debris that may have collected over the year.

Combining wireless monitoring systems with traps that use venturi orifice technology is the ultimate low maintenance, low cost solution for any site. No more spare parts, hours fixing and determining problems or wastage of precious live steam. The ultimate solution.

0 Comments

|

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed