|

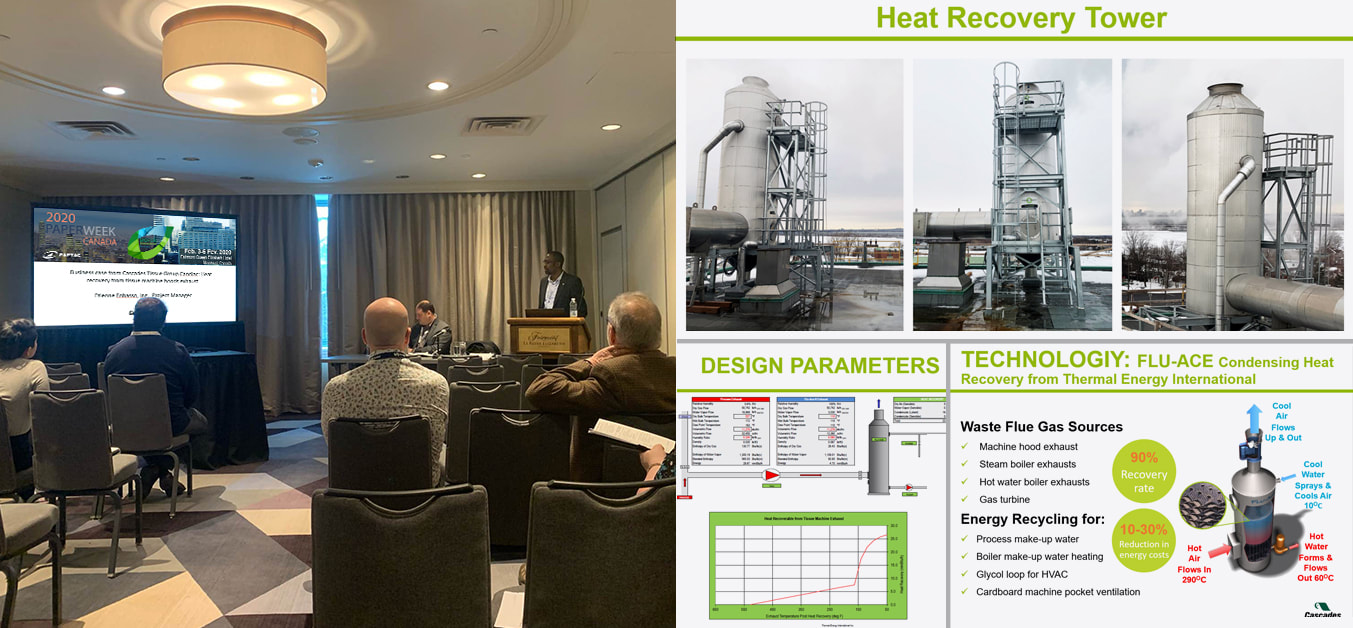

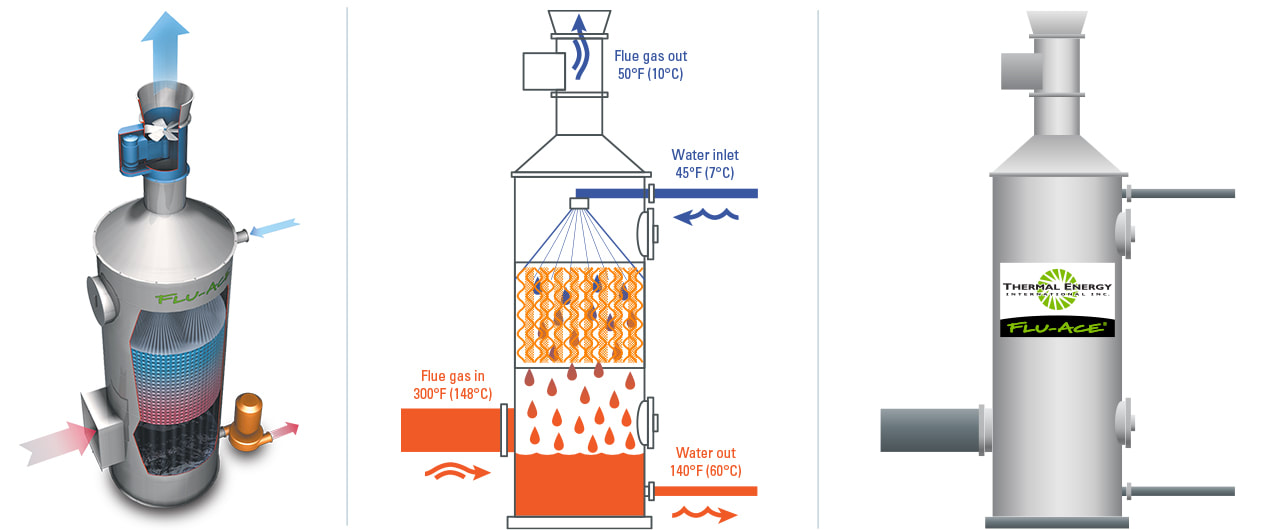

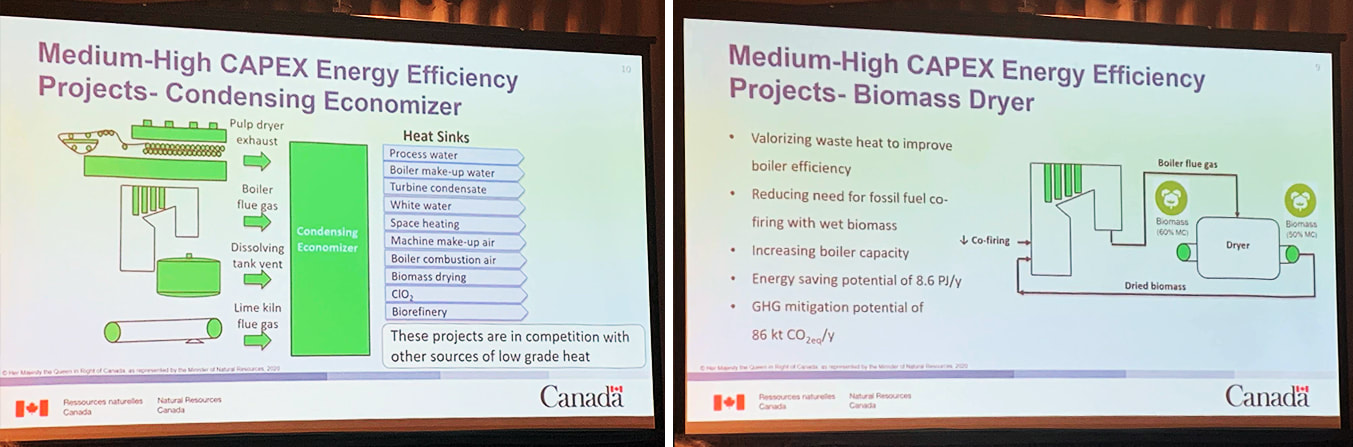

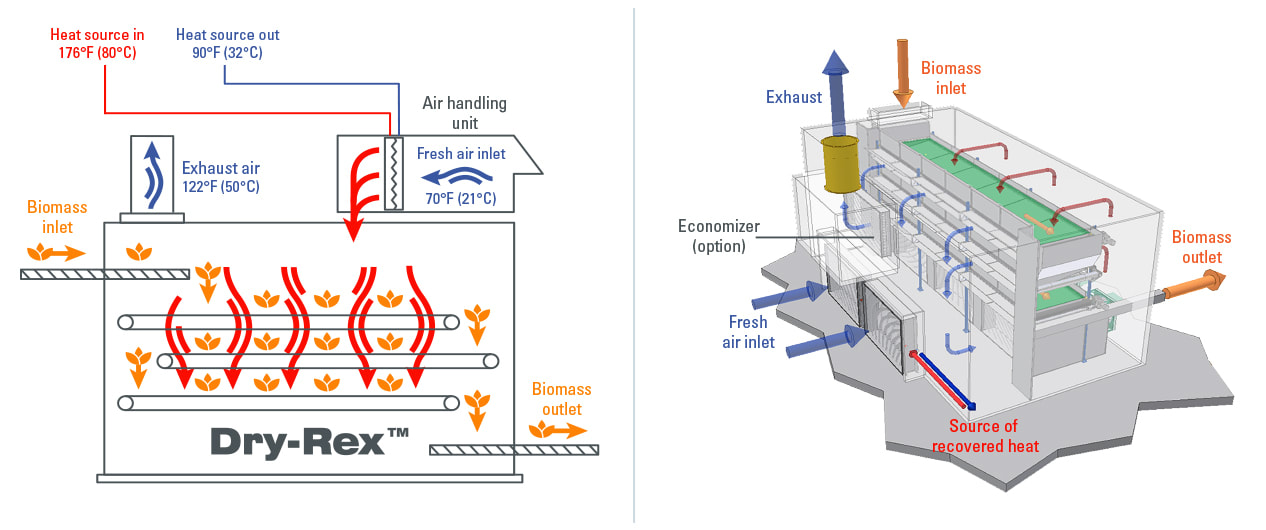

Last week, Thermal Energy attended PaperWeek Canada 2020, at the Fairmont Queen Elizabeth Hotel in Montreal. As PAPTAC’s flagship conference and tradeshow, serving the pulp, paper, and forest products industry, it is a valuable platform for exchanging industry best practices with pulp and paper mills from across the country, as well as showcase Thermal Energy’s energy-efficiency solutions. Antoine Hofer, Technical Sales Director, Quebec and Eastern Canada at Thermal Energy, had this to say about the event: “PaperWeek was excellent this year, which is what we’ve come to expect from the show. A professional event with expert speakers, discussing current issues that effect mills, suppliers, and customers - both in Canada and globally - as well as innovations that enable the industry to evolve to meet new challenges.” Cascading savings On Thursday, during the Energy Technical session on the “Certification process for the ISO 50001 at Cascades", Cascades CS+ Inc. Project Manager, Etienne Fobasso, Ing. presented a business case from the Cascades Candiac Tissue Group on how their energy team, in partnership with Thermal Energy, effectively recovers wasted heat from tissue machine hoods exhaust. The case involved the replacement of the existing direct contact heat recovery water tower with Thermal Energy’s revolutionary FLU-ACE® Condensing Heat Recovery System. Founded in 1964, Cascades produces, converts and markets packaging and tissue products composed mainly of recycled fibres, and employs 11,000 employees, working in 90 units in North America and Europe. The new system enables the Candiac site to recover waste flue gas energy from the tissue machine exhaust. This is possible using the FLU-ACE®’s unique direct contact (gas/liquid) packed-tower design, enabling optimal recovery of both sensible and latent heat, in widely varying operating conditions. The recovered energy can then be used by Cascades to heat water for the clarifier water chest (showers and bleaching) and the glycol loop for two (2) HVAC units (130,000 cfm total). Additional environmental benefits of the enhanced system include saving the mill over 62,800 MMBtu of natural gas annually, as well as reducing greenhouse gases, resulting from fuel combustion, by over 3,300 tons per year. Read about other paper mill success stories on our Pulp and Paper page. Carbon neutral pulp and paper On Thursday morning, Sara Eskandarifar from CanmetENERGY, delivered an interesting Energy Technical session on the benefits of moving "Towards a carbon neutral pulp and paper industry: overview of available technologies". In her session, Sara described the use of condensing heat recovery technology like the FLU-ACE®, as well as low-temperature biomass drying as a means of recovering energy from existing processes and waste streams and improving the boiler efficiency. Where biomass is already in use as a fuel source, Thermal Energy’s DRY-REX biomass dryer can completely eliminate the need to use non-renewable fossil fuels. The process involves in the application of waste heat to dry alternative fuel. The efficient rugged constructed solution operates at low temperatures of 10°C to 93°C with an impact of 5-10% efficiency, and a typical return on investment of 2-5 years. High-fibre packaging As more and more businesses opt for more environmentally-friendly packaging over single use plastic, the Pulp and Paper sector have an opportunity and a responsibility to provide innovative, sustainable, fibre-based options. On Tuesday, during the PaperWeek Canada 2020 keynote luncheon panel on ‘Next Generation Fibre-based Packaging – An Effective Way to Reduce Plastic Waste?’ the panelists discussed the latest advancements and projections for the increased use of sustainable fibre-based packaging in consumer markets as an alternative to single-use plastic products.

As an innovative technology company that supplies energy efficient solutions that are engineered to help the pulp and paper, and other industries, save money by operating more sustainably - through increased energy efficiency, reduced fossil fuel usage, GHGs and other emissions - Thermal Energy is an active supporter of reduced global pollution.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

August 2021

Categories

All

|

RSS Feed

RSS Feed